Welcome to the official website of iSonics Smart Clean Jiangsu Co.,Ltd!

- Pay attention to wechat

Pay attention to wechat

Pay attention to wechat - 中文

Welcome to the official website of iSonics Smart Clean Jiangsu Co.,Ltd!

Pay attention to wechat

Pay attention to wechat

Address:

18 Xinjing Middle Road, Zhangjiagang City, Suzhou

Address:

18 Xinjing Middle Road, Zhangjiagang City, Suzhou

Landline:

18651121666

Landline:

18651121666

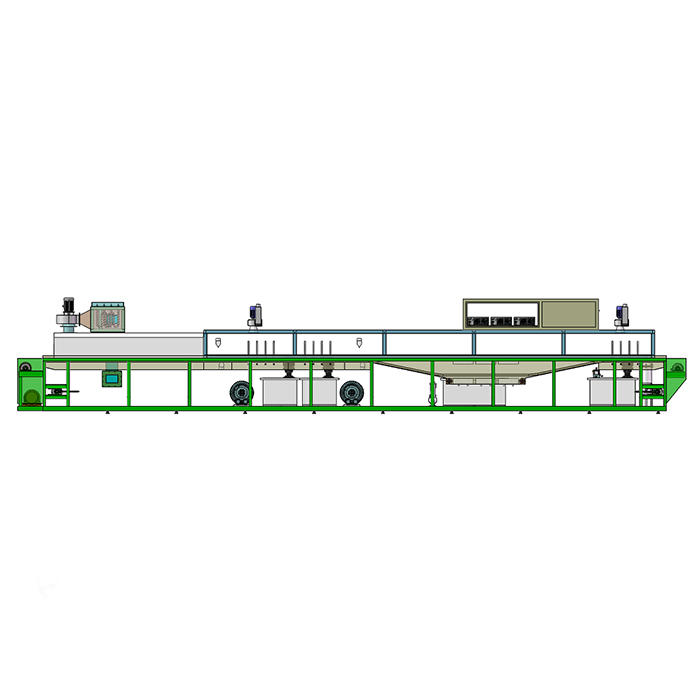

Overview: This equipment is suitable for removing oil, polishing paste, dust and other impurities from automobile and motorcycle parts, hardware and mechanical parts. The equipment has a spray cleaning room, an ultrasonic cleaning room, a spray rinsing room, a compressed air water cutting room, a hot air drying room, a total of 5 stations. Its working principle is to manually place the workpiece to be cleaned on the stainless steel crawler, and then clean it according to a certain process procedure and discharge the material. The equipment has beautiful appearance, reasonable structure and long service life. It is an ideal metal cleaning equipment.

---This equipment has the following characteristics:

---1. Automatic transmission of cleaning workpieces;

---2. The upper and lower sides of the ultrasonic vibrator radiate;

---3. Spray rinsing can remove residual cleaning fluid on the workpiece and reduce secondary pollution;

---4. Add a storage tank and a cleaning fluid circulating filter system to ensure cleanliness;

---5. The special stainless steel mesh belt is made of a special process to make the equipment safe and reliable;

---6. According to the cleanliness requirements of the workpiece, the cleaning time can be adjusted arbitrarily;

---7. The electrical part and the control box are connected to the whole machine for easy installation and operation;

---8. The upper dust cover makes the equipment complete and beautiful.

--- Three, the main composition of the equipment

---1. 1 set of loading and unloading stations (loading and unloading at both ends of the main line of the equipment)

---2. Spray cleaning system 1 set

---3. Ultrasonic cleaning system 1 set

---4. 1 set of spray rinsing system

---5. Compressed air water cutting system 1 set

---6. 1 set of hot air drying system

---7. Bracket 1 set

---8. 1 set of stainless steel track

---9. Outer envelope 1 set

---10. 1 set of electric control system

---Main process flow

---1. Cleaning process: manual feeding→spray cleaning→ultrasonic cleaning→spray rinsing→compressed air cutting water→hot air drying→manual unloading (if the workpiece has accumulated water, manually use an air gun to make up)

---Scope of application:

---1. Machinery industry: bearings, oil pump nozzles, engine parts, automobile and motorcycle parts, compressor parts, metal stamping machines and other precision parts;

---2. Electronic industry: electronic components, circuit boards, glass lenses, semiconductors, magnetic materials, etc.;

---3. Hardware industry: medical equipment, hardware tools, etc.;

---4. Other industries: stainless steel barrels, special pipe fittings, etc.

---Note: This equipment is customized according to the characteristics of cleaning products and non-standard design according to actual requirements. It has strong flexibility and can be used in the cleaning process of equipment in various industries.

Third, the main components of the equipment

---1. 1 set of loading and unloading stations (loading and unloading at both ends of the main line of the equipment)

---2. Spray cleaning system 1 set

---3. Ultrasonic cleaning system 1 set

---4. 1 set of spray rinsing system

---5. Compressed air water cutting system 1 set

---6. 1 set of hot air drying system

---7. Bracket 1 set

---8. 1 set of stainless steel track

---9. Outer envelope 1 set

---10. 1 set of electric control system